When it comes to HVAC systems, efficiency and reliability are non-negotiable. Rotary screw air compressors have become a go-to solution for many industries, offering smoother operation and longer lifespans compared to traditional reciprocating units. With up to 100,000 operational hours, these systems are built to last, making them a smart investment for your facility1.

Imagine the steady hum of a well-maintained compressor in a busy manufacturing plant—this is the sound of efficiency. Rotary screw compressors are designed for continuous use, delivering consistent compressed air with minimal downtime. Their advanced technology ensures energy savings, reducing your overall operational costs2.

This guide will walk you through the essentials of operation and maintenance, helping you get the most out of your equipment. Whether you’re in manufacturing or running service trucks, understanding your system’s needs is key to its longevity.

Key Takeaways

- Rotary screw compressors offer up to 100,000 operational hours, ensuring long-term reliability.

- They provide smoother operation and energy savings compared to traditional units.

- Proper maintenance is essential for maximizing efficiency and lifespan.

- These compressors are ideal for continuous use in various industries.

- Understanding your system’s requirements can significantly reduce operational costs.

Opening: Tackling HVAC Challenges with an Expert Perspective

Ever felt the frustration of an HVAC system that just won’t cooperate? Whether it’s inconsistent airflow, rising energy bills, or unexpected downtime, these issues can disrupt your daily operations and strain your budget. Let’s dive into the common pain points and explore practical solutions to keep your system running smoothly.

Identifying Your System’s Pain Points

One of the most common issues is inconsistent airflow, which can lead to uneven cooling or heating. This often stems from clogged filters or ductwork problems. A dirty air filter can reduce energy efficiency by up to 10%, driving up your bills3.

Another challenge is high energy consumption. If your system isn’t maintained, it can consume more power than necessary. Regular maintenance can reduce energy use by 5% to 20%, saving you thousands annually4.

The Promise of a Practical Solution

Imagine a scenario where your HVAC system operates at peak efficiency, with minimal downtime and lower costs. This isn’t just a dream—it’s achievable with the right approach. Start by scheduling regular inspections and replacing air filters every three months3.

Investing in predictive maintenance technologies can also enhance operational efficiency. These tools help identify potential issues before they escalate, ensuring your system runs smoothly4.

By addressing these pain points, you can extend the lifespan of your equipment, reduce maintenance costs, and enjoy consistent comfort in your facility.

The Essentials of How a Rotary Screw Air Compressor Operates

Understanding how a rotary screw air compressor works can unlock its full potential. These systems are designed to deliver consistent compressed air with minimal downtime, making them a reliable choice for various applications. Let’s break down the process and explore the key differences between oil-injected and oil-free techniques.

Understanding the Air Compression Cycle

The journey begins with atmospheric air entering the system. Inside, two intermeshed rotors work together to reduce the air volume, creating high-pressure output. Think of it like squeezing a sponge—the more you compress, the more air is released. This process is continuous, allowing the system to operate at a 100% duty cycle5.

Rotary screw air compressors deliver 4-5 CFM per horsepower, outperforming traditional units by 20-25%5. This efficiency makes them ideal for demanding environments where consistent airflow is critical.

Oil-Injected Versus Oil-Free Techniques

Oil-injected models use oil to lubricate the rotors and cool the system. This results in smoother operation and cooler temperatures, making them a popular choice for continuous use6. However, oil-free models are preferred in industries like food and pharmaceuticals, where air quality is paramount.

Oil-free systems require two stages of compression to achieve the same pressure levels, which can increase costs6. Despite this, they provide cleaner air, meeting strict industry standards. Both options have their unique benefits, so choosing the right one depends on your specific needs.

By understanding these processes, you can make informed decisions about your equipment. Proper maintenance and operation will ensure your system runs efficiently for years to come.

Exploring the Key Components of an HVAC Compressor System

At the core of every HVAC system lies a network of components working in harmony. Each part plays a vital role in ensuring smooth operation and long-term reliability. Let’s take a closer look at the essential elements that make your system tick.

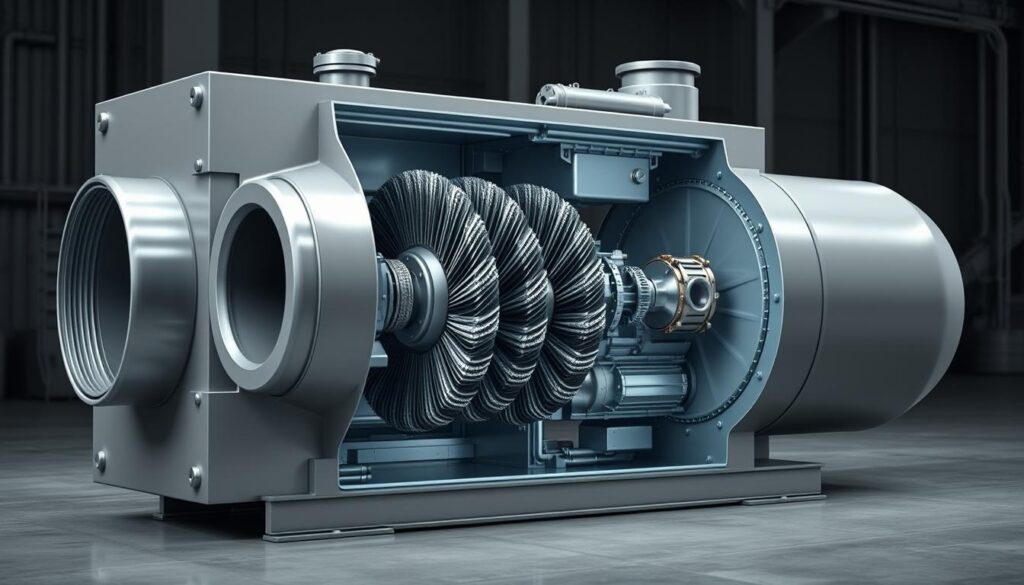

Air-End and Rotor Dynamics

The air-end is the beating heart of your system, where compressed air is generated. Inside, two intermeshed rotors work together to reduce air volume, creating high-pressure output. Think of it like the engine of a finely tuned sports car—every movement is precise and efficient7.

Rotor dynamics ensure continuous positive displacement, allowing the system to operate at a 100% duty cycle. This design minimizes wear and tear, extending the lifespan of your equipment8.

Cooling, Filtration, and Oil Circulation Systems

Cooling systems, like aftercoolers, are essential for dissipating heat generated during compression. Without proper cooling, the system could overheat, leading to inefficiency or even failure7.

Filtration systems, including intake and inline filters, maintain air quality by removing contaminants. Clean air not only improves performance but also protects other components from damage8.

Oil circulation techniques ensure smooth operation by lubricating moving parts. Oil separators play a crucial role in maintaining system efficiency by removing excess oil from the air stream9.

| Component | Function | Benefit |

|---|---|---|

| Air-End | Generates compressed air | High efficiency, minimal wear |

| Aftercooler | Dissipates heat | Prevents overheating |

| Inline Filter | Removes contaminants | Improves air quality |

| Oil Separator | Removes excess oil | Enhances system efficiency |

By understanding these components, you can better appreciate the complexity and reliability of your HVAC system. Regular maintenance ensures each part performs optimally, keeping your system running smoothly for years to come.

Installation Insights and System Design Considerations

Installing a new air system requires careful planning and attention to detail. Whether you’re upgrading an existing setup or starting from scratch, the right approach ensures seamless integration and long-term efficiency. Let’s explore the key factors to consider during installation and design.

Site Selection and Environmental Factors

Choosing the right location is critical for optimal performance. Ensure the space has adequate ventilation and is free from dust, moisture, or corrosive elements. Ambient temperature should be controlled, as extreme conditions can impact system reliability10.

Allocate enough room for routine maintenance and inspections. A well-ventilated area not only extends the lifespan of your equipment but also enhances safety during operation10.

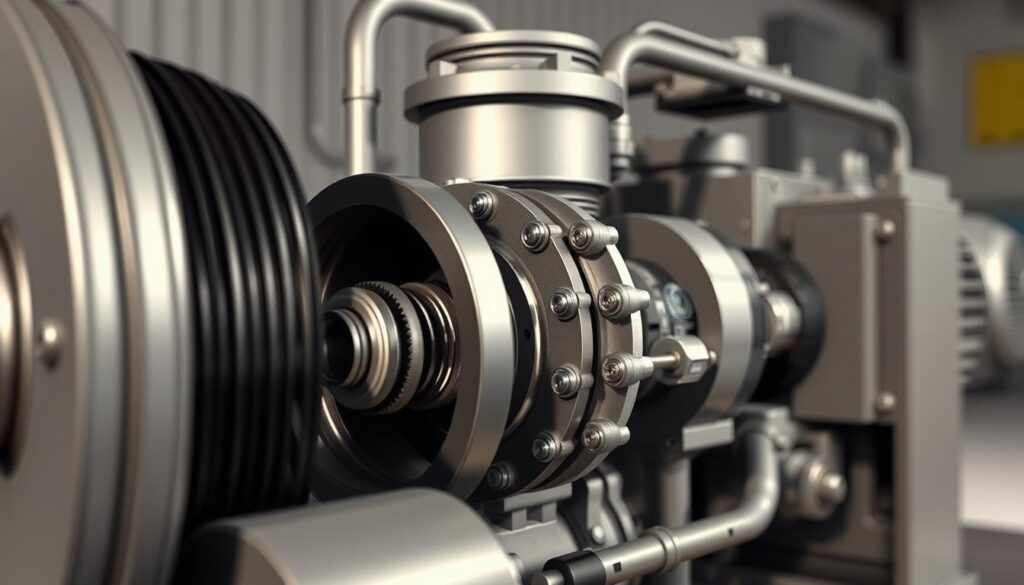

Integration with Existing Components

When integrating a new system, compatibility with existing air receiver tanks and dryers is essential. Properly sized piping minimizes pressure drop, improving overall efficiency11. Use nonferrous materials for inlet piping to prevent contamination and ensure durability.

Follow the manufacturer’s guidelines for wiring and mounting. Adhering to safety codes and standards prevents potential hazards and ensures smooth operation10.

Design Best Practices

Efficient design starts with understanding your facility’s needs. For example, retrofitting a modern screw compressor into an older system requires careful planning. Match the compressor’s capacity to your air demand to avoid unnecessary energy consumption12.

Incorporate energy-efficient features like variable speed drives (VSDs) to reduce power usage by 30-70%12. Proper air storage capacity, typically 3-5 gallons per CFM output, ensures consistent performance during peak demand11.

By focusing on these installation and design considerations, you can maximize the efficiency and longevity of your system. A well-planned setup not only saves energy but also reduces operational costs over time.

Maintenance Best Practices to Extend Your Compressor’s Lifespan

Keeping your air system in top shape doesn’t have to be complicated. With a few simple steps, you can ensure it runs smoothly for years to come. Regular care not only prevents costly breakdowns but also maximizes efficiency and performance.

Routine Service and Inspection Guidelines

Daily checks are the foundation of good maintenance. Start by verifying oil levels and inspecting condensate traps. Clean filters regularly to prevent contamination and ensure optimal airflow13.

For oil-flooded systems, change the oil every 8,000 hours or annually. Food-grade lubricants should be replaced every 4,000 hours to maintain quality13. Regularly test oil for varnish and other issues every 2,000 hours14.

Periodic professional servicing is equally important. Schedule inspections to check motor bearings, separator elements, and other critical parts. Replace separator elements every 2,000-8,000 hours to avoid excessive oil usage14.

Skilled Troubleshooting and Preventative Measures

Unusual sounds or vibrations can signal underlying issues. Address air leaks promptly, as they can divert 25-30% of your compressed air14. Overheating is another common problem; monitor temperatures to ensure they stay within safe limits.

Here are some quick troubleshooting tips:

- Check for loose hoses or couplings, especially in the last 30 feet of your system14.

- Inspect filters for clogs and replace them as needed.

- Ensure proper ventilation to prevent overheating, particularly in larger systems13.

By following these steps, you can extend your system’s lifespan and reduce operational costs. Preventative maintenance is an investment that pays off in the long run.

Understanding the Economic Benefits and Energy Efficiency of the System

Investing in a reliable air system can significantly impact your bottom line. Beyond the initial cost, the long-term savings and energy efficiency of modern systems make them a smart choice for any facility. Let’s explore how these systems deliver economic value and operational reliability.

Cost of Ownership and Long-Term Savings

While the upfront investment in a high-quality air system may seem steep, the long-term savings are substantial. Over the first ten years, operating costs—like electricity and maintenance—account for about 88% of the total lifetime cost15. This means focusing on energy-efficient models can drastically reduce expenses.

For example, implementing Variable Speed Drives (VSDs) can cut energy consumption by up to 50% during low-demand periods16. Regular maintenance, such as fixing leaks and lowering air pressure, can save 10-20% on energy costs annually15.

Energy Efficiency Metrics and Analysis

Energy efficiency is a key factor in reducing operational costs. Modern systems are designed to minimize waste, with some models delivering 4-5 CFM per horsepower, outperforming older units by 20-25%16. This efficiency translates into lower utility bills and a faster return on investment.

Here are some key metrics to consider:

- CFM per horsepower: Measures airflow efficiency, with higher values indicating better performance.

- Oil carryover: Lower levels reduce downtime and maintenance needs, enhancing overall efficiency15.

- Energy consumption: Systems with smart controllers optimize energy use, reducing costs during low-demand periods16.

By choosing energy-efficient equipment and adhering to maintenance best practices, you can maximize savings and extend the lifespan of your system. The economic benefits are clear: lower costs, improved ROI, and reliable performance.

Performance Benchmarks and Relevant Industry Statistics

Performance metrics are the backbone of any efficient air system. Understanding key benchmarks like Cubic Feet per Minute (CFM), Pounds per Square Inch (PSI), and duty cycles can help you optimize your equipment. These numbers not only reflect efficiency but also influence long-term reliability and cost savings.

CFM, PSI, and Duty Cycle Comparisons

CFM measures the volume of air a system can deliver. For example, flow rates for compressed air can start as low as 3.5 CFM and extend beyond that, depending on the application17. PSI, on the other hand, indicates the pressure level. Compressed air applications range from 14 PSI to 6004 PSI, making it versatile for various industries17. Duty cycle refers to the percentage of time a system can operate without overheating. Standard compressors typically range from 50% to 100% duty cycles17.

Rotary screw compressors often outperform reciprocating models in these areas. They deliver higher CFM per horsepower and maintain consistent pressure levels, even during continuous operation18. This makes them ideal for demanding environments where reliability is critical.

Impact on HVAC Efficiency

Performance metrics directly influence the efficiency of your HVAC system. For instance, a 1% increase in power consumption occurs for every 2% rise in pressure19. By optimizing CFM and PSI, you can reduce energy usage and lower operational costs. Additionally, systems with higher duty cycles minimize downtime, ensuring consistent performance.

Here’s a quick comparison of rotary screw and reciprocating compressors:

- CFM Output: Rotary screw models deliver 4-5 CFM per horsepower, outperforming reciprocating units by 20-25%18.

- PSI Levels: Rotary screw compressors maintain stable pressure, even under heavy loads.

- Duty Cycle: Rotary screw systems can operate at 100% duty cycles, making them suitable for continuous use.

By focusing on these benchmarks, you can make informed decisions about your equipment. Whether you’re upgrading or maintaining your system, understanding these metrics ensures optimal performance and long-term savings.

Real-Life Experiences: Stories and Sensory-Rich Case Studies

Imagine walking into a facility where the hum of machinery is steady, efficient, and uninterrupted. This isn’t just a dream—it’s the reality for many businesses that have embraced modern air systems. Let’s dive into some real-life stories that showcase the transformative power of these technologies.

Testimonials from the Field

One manufacturing plant in Ohio saw a 30% reduction in downtime after upgrading to a screw compressor. The facility manager described the change as “night and day,” with smoother operation and fewer breakdowns20.

Another company in Texas reported significant energy savings after switching to a compressed air system. Their monthly utility bills dropped by 15%, and the system’s reliability improved dramatically.

Data-Driven Examples and Trends

Data shows that businesses using modern air compressors experience up to 25% higher efficiency compared to older models. This translates to lower operational costs and improved productivity.

Here’s a quick look at some key improvements:

- Reduced Downtime: Facilities report up to 40% fewer interruptions in operation20.

- Energy Savings: Systems with advanced technology cut energy use by 15-20%.

- Consistent Performance: Users praise the reliability of these systems, even under heavy loads.

These stories and numbers highlight the real-world benefits of investing in the right equipment. Whether it’s reduced downtime, energy savings, or consistent performance, the results speak for themselves.

How to Troubleshoot and Optimize Your Rotary Compressor Guide Performance

Efficient troubleshooting can save you time and money while keeping your system running smoothly. By identifying and addressing issues early, you can prevent costly downtime and extend the lifespan of your equipment. Let’s explore common problems and practical solutions to optimize your system’s performance.

Identifying Common Issues and Their Solutions

One of the most frequent problems is air leaks, which can lead to significant pressure loss and reduced efficiency. Regularly inspect hoses, couplings, and valves for leaks, especially in the last 30 feet of your system21. Fixing leaks promptly can save up to 30% of your compressed air22.

Another issue is overheating, often caused by low oil levels or clogged aftercoolers. Check oil levels weekly and use OEM-approved oil to maintain proper lubrication21. Clean aftercoolers regularly to prevent blockages and ensure efficient cooling22.

Systematic Troubleshooting Checklist

Here’s a step-by-step guide to diagnosing and fixing common problems:

- Check for air leaks: Use soapy water to identify leaks in hoses and connections21.

- Inspect oil levels: Ensure oil is at the recommended level and free from contamination22.

- Monitor pressure levels: Verify that your system maintains consistent pressure during operation23.

- Clean filters: Replace or clean air filters to prevent airflow restrictions22.

- Listen for unusual sounds: Grinding or rattling noises may indicate misaligned or worn components22.

Optimizing Performance Through Maintenance

Regular maintenance is key to keeping your system efficient. Schedule oil changes every 2,000 to 8,000 hours, depending on usage23. Clean or replace separator elements to prevent excessive oil consumption21.

Calibrate built-in diagnostic tools to monitor performance metrics like pressure and temperature. These tools can alert you to potential issues before they escalate, reducing downtime and repair costs23.

When to Call a Professional

While many issues can be resolved with simple fixes, some problems require expert attention. If you notice persistent pressure drops, excessive oil carryover, or frequent shutdowns, contact a certified technician22. Professional servicing ensures your system operates at peak efficiency and extends its lifespan.

By following these tips, you can keep your system running smoothly and avoid costly repairs. A proactive approach to troubleshooting and maintenance ensures reliable performance and long-term savings.

Exploring the Future of HVAC Technology and Compressor Innovation

The future of HVAC technology is evolving at a rapid pace, bringing innovative solutions to the forefront. From smart systems to eco-friendly designs, the industry is transforming to meet modern demands. Let’s dive into the trends shaping the next generation of HVAC equipment.

Emerging Trends and Research Insights

One of the most exciting advancements is the integration of digital monitoring systems. These tools allow you to track performance in real-time, ensuring optimal efficiency. For example, manufacturers are now incorporating AI and IoT to predict maintenance needs before issues arise24.

Another trend is the rise of variable speed drives (VSDs). These systems adjust power usage based on demand, reducing energy consumption by up to 50% during low-load periods25. This not only saves money but also extends the lifespan of your equipment.

Eco-Friendly Innovations

Sustainability is a key focus in modern HVAC design. New models are being developed to minimize environmental impact. For instance, scroll compressors are gaining popularity due to their energy efficiency and reduced greenhouse gas emissions25.

These systems also have fewer moving parts, which means less friction and lower maintenance costs25. By choosing eco-friendly options, you can contribute to a greener future while enjoying long-term savings.

Balancing Tradition and Innovation

While new technologies are exciting, traditional designs still have their place. For example, RIGID’s mini-compressors combine compact size with reliable performance, proving that innovation doesn’t mean sacrificing quality24.

Here’s a quick comparison of traditional vs. innovative systems:

| Aspect | Traditional Systems | Innovative Systems |

|---|---|---|

| Energy Efficiency | Moderate | High |

| Maintenance Needs | Frequent | Minimal |

| Environmental Impact | Higher | Lower |

| Cost Over Time | Higher | Lower |

By embracing these advancements, you can future-proof your HVAC system and stay ahead in a competitive industry. Whether it’s through smart technology or sustainable designs, the possibilities are endless.

Conclusion

Optimizing your air system’s performance starts with understanding its core benefits and practical applications. From smoother operation to reduced energy consumption, modern systems like the screw compressor offer significant advantages for various applications26.

Take a moment to review your current setup. Are you maximizing efficiency and minimizing downtime? Small adjustments, like fixing leaks or upgrading components, can lead to long-term savings and improved reliability27.

Ready to take the next step? Start with a self-audit of your system’s processes and identify areas for improvement. Whether it’s enhancing airflow or reducing noise levels, these changes can transform your equipment’s performance28.

For expert guidance, connect with professionals who can provide tailored solutions. Together, you can ensure your system meets the demands of your industry while delivering consistent results. Let’s move forward with innovation and efficiency—your air system deserves it.

FAQ

What are the main benefits of using a rotary screw air compressor in HVAC systems?

How does the air compression cycle work in a rotary screw compressor?

What’s the difference between oil-injected and oil-free rotary screw compressors?

What are the key components of an HVAC compressor system?

How can I integrate a rotary screw compressor into my existing HVAC infrastructure?

What maintenance practices can extend the lifespan of my compressor?

How does a rotary screw compressor improve energy efficiency?

What are CFM, PSI, and duty cycle, and why are they important?

What are some common issues with rotary screw compressors, and how can I troubleshoot them?

What emerging trends are shaping the future of HVAC compressor technology?

Source Links

- The Complete Guide to Rotary Compressors

- Common HVAC Issues That Can Lead to System Replacement

- Operations & Maintenance Best Practices Release 2.0

- Full Guide to Rotary Screw Air Compressors

- Easy Guide To Rotary Screw Air Compressors – 2024 Edition

- What is an HVAC Compressor? | Logan Services A/C, Heat & Plumbing

- What is Compressor in HVAC: Everything You Need to Know

- The Crucial Role of Compressors in HVAC Systems: A Comprehensive Guide

- Things to Consider When Installing Centrifugal Compressors

- Compressed Air System Design Services | Fluid-Aire Dynamics

- How to Design a Compressed Air System – Fluid-Aire Dynamics

- How to Extend the Lifespan of Your Air Compressor – Kaishan USA

- How to Extend Your Air Compressor Life Expectancy

- Energy Efficiency Reference Guide Compressed Air

- 8 Benefits of Energy Efficient Compressed Air System – Atlas Copco

- Air Compressor Statistics and Facts (2025)

- CAGI Air Compressor Performance Verification and Testing Results

- CAGI Performance Verification Program for Air Compressor and Dryer Selection

- The Servo ventilator story

- TROUBLESHOOTING YOUR ROTARY VANE COMPRESSOR

- Rotary Screw Compressor Troubleshooting

- Rotary Screw Compressors: Maintenance Best Practices for Enhanced Performance | Air Handling Equipment

- Exploring Scroll Compressor vs Reciprocating Compressor in HVAC

- Unlocking Efficiency: A Comprehensive Guide to Scroll Compressors – Panrui Compressor Co. , Ltd.

- Rotary Screw Air Compressors | The Comprehensive Guide

- The Ultimate Guide to Choosing a Small Rotary Compressor

- ELGi IN EUROPE

0 Comments